Understanding the Differences

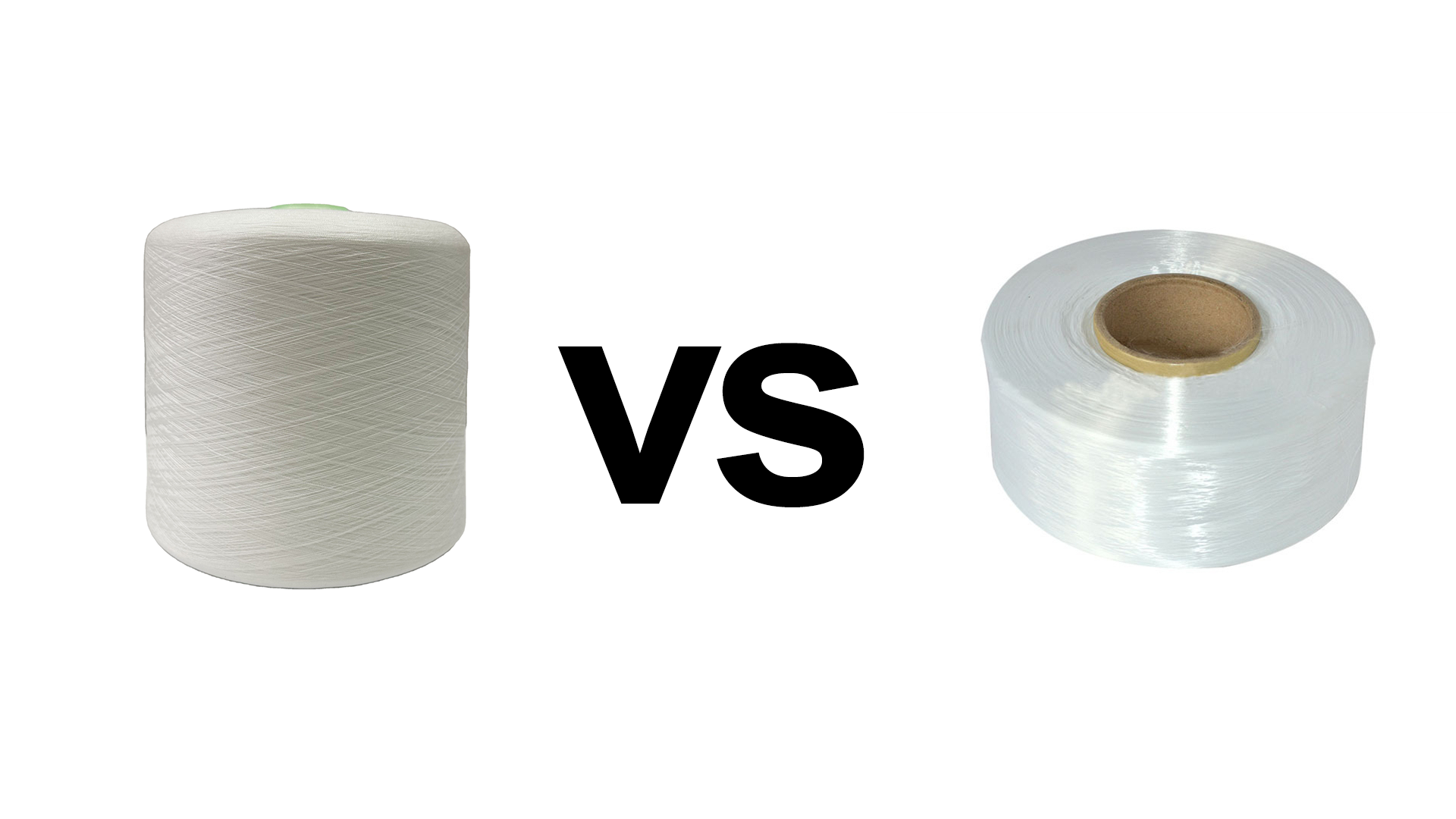

Polyester staple fiber and polyester filament are two primary forms of polyester used in textile manufacturing. While both originate from the same polymer, their structural differences lead to distinct characteristics and applications.

Structural Differences

Polyester filament consists of long, continuous strands of polyester, extruded directly from the polymer melt through spinnerets. These filaments can be further processed into various forms, such as partially oriented yarn (POY), drawn textured yarn (DTY), or fully drawn yarn (FDY), depending on the intended application. In contrast, polyester staple fiber is produced by cutting the continuous filaments into shorter lengths to mimic the length of natural fibers like cotton or wool.

Mechanical Properties

The continuous nature of polyester filaments imparts higher tensile strength and durability, making them suitable for applications requiring robust materials. These include industrial fabrics, outdoor textiles, and high-performance apparel. Polyester staple fibers, being shorter and often processed into spun yarns, offer a softer feel and are more akin to natural fibers, making them ideal for products like bedding, casual wear, and home textiles.

Aesthetic and Functional Considerations

Fabrics made from polyester filaments tend to have a smoother surface and a natural sheen, contributing to a more luxurious appearance. The uniformity of filament fibers allows for consistent texture and color, which is advantageous in high-end fashion and uniform textile production. On the other hand, polyester staple fibers, due to their shorter length and spun processing, can achieve a more textured and matte finish, which is often preferred in casual and comfort-oriented textiles.

Applications in the Textile Industry

Polyester filaments are predominantly used in applications where strength and durability are paramount. These include manufacturing ropes, tire cords, and certain types of industrial fabrics. They are also utilized in the production of high-performance apparel and technical textiles. Conversely, polyester staple fibers are widely used in the production of spun yarns for woven and knitted fabrics, catering to a broad range of products from clothing to home furnishings.

Conclusion

In summary, the choice between polyester staple fiber and polyester filament depends on the specific requirements of the end product. While filaments offer superior strength and a sleek finish suitable for technical applications, staple fibers provide a softer, more natural feel, making them ideal for everyday textiles. Understanding these differences is crucial for manufacturers and consumers alike in selecting the appropriate material for their needs.